How to Pack Products Securely Without Plastic

If your business still relies on plastic packaging, now’s the time to rethink your approach. Plastic comes with environmental drawbacks, and in many areas, regulations are already phasing it out. The good news? You can pack and ship products just as securely without using any plastic at all.

In this blog, we’ll cover:

- The problem with plastic packaging and what to use instead

- How to choose alternative packaging materials and dispensers

- How to secure bulk shipments

Plastic packaging is already becoming obsolete in some U.S. states. By switching to paper-based alternatives now, you can stay ahead of new regulations and boost your brand’s reputation, all without compromising product protection.

The Problem With Plastic Packaging

Plastic has long been the go-to material for product protection (think bubble cushioning, plastic mailers, and air pillows. But while it may be cheap and convenient, plastic packaging comes with serious environmental and health concerns that are impossible to ignore.

The biggest issue? Plastic is incredibly slow to decompose, taking anywhere from 10 years to several centuries to break down. And most of it never even gets recycled. Even plastics labeled “recyclable,” typically require specialized processing facilities, which many communities simply don’t have access to. As a result, plastic packaging winds up in landfills, or worse, as litter in our environment. Over time, it breaks into microplastics, polluting our soil, waterways, and even the air. These particles have been found in drinking water, food, and the human body, raising growing concerns about long-term health impacts.

Some plastics also leach chemicals during use and disposal, putting both customers and employees at risk, especially those who handle plastic packaging regularly. Because of these risks, some U.S. states and global organizations, such as the European Union, are now phasing out plastic packaging altogether.

Luckily, there’s a better way. Kraft paper packaging offers a sustainable alternative that’s safer for people and the planet. Products like those from HexcelPack are:

- Made from renewable resources.

- Produced with a minimal impact on the planet.

- Safe for every day handling.

They’re also curbside recyclable, compostable, and 100% biodegradable, making them easy for your business and your customers to dispose of responsibly. Some customers have even found creative ways to reuse them, like adding them to compost bins or using them in the garden.

And beyond compliance, switching to sustainable packaging is a smart business move. Today’s customers are actively seeking sustainable brands and are even willing to pay more for products that are packaged responsibly.

How to Choose Packaging Materials and Dispensers

Choose the Right Tertiary Packaging

It all starts with selecting the best outer container for the job. For many businesses, that’s a cardboard box (ideally once that’s uncoated and recyclable). Your shipping box should be large enough to hold both the product and protective packing materials. But the box shouldn’t be so oversized that you waste packaging or increase your shipping costs unnecessarily.

Oversized packaging can also frustrate customers. You’ve likely experienced this yourself–receiving a large box for a small item only to struggle with recycling it or finding space for it in the bin.

Add Protective Packaging Inside

Once you’ve chosen your outer container, it’s time to protect the items inside. If you’re using a box, you’ll likely need both product wrap and void fill.

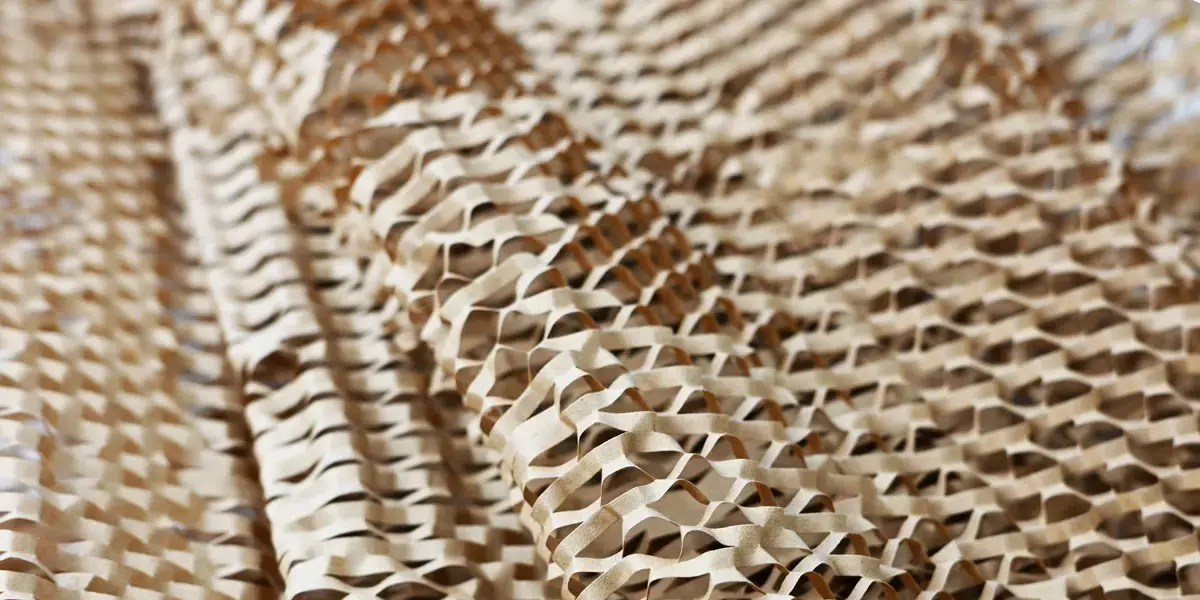

- Product wrap, like HexcelWrap®, is designed to protect fragile items such as glassware, ceramics, or artwork that need extra cushioning. Its expandable honeycomb design conforms to the shape of your product and holds securely without the need for tape or adhesives. It can be dispensed manually in a number of scenarios, like at the checkout counter or in the back of your shop. It’s also flexible enough to be used everywhere from art fairs to fulfillment centers, depending on the size of your business.

- Void fill, such as HexaFil™, is used to fill empty space within the box to prevent items from shifting during transit. It keeps products stable and helps minimize damage from movement.

Honeycomb packaging, like these products from HexcelPack, interlock for added stability during shipping. Plus, the Kraft paper resists compression better than plastic alternatives, meaning you use less material while maintaining a high level of protection.

Dispensing Made Easy

HexcelPack offers both manual and automated dispensers for its sustainable packaging products, and many businesses find that using a combination of both works best for their packaging setup.

- Automated dispensing, like the AutoHexaFil™ dispenser, is ideal for high-volume operations. With programmable cut-to-length settings and hands-free foot pedal control, it speeds up packing while reducing material waste and ensuring consistency.

- Manual dispensing remains a popular choice for businesses of all sizes. These dispensers don’t require power, are easy to use with little training, and have no wearable parts, making them low-maintenance and cost-effective. Many businesses even find manual systems faster for certain workflows due to their simplicity. HexcelPack’s lineup of manual dispensers includes the Mini Pack™ (available in MP 300 and MP 1400), the Mini Packing Station™, the Manual HexaFil™ unit, and the HexaFil™ Fil in a Box™, all designed for intuitive, power‑free use.

By combining both methods, you get the flexibility to scale your operation without compromising speed or protection.

How to Secure Bulk Shipments

Once your products are packed, the next step is often storing or shipping them in bulk. Placing multiple boxes on a pallet is one of the most efficient ways to move large quantities—whether you're transporting them across a warehouse or shipping to a fulfillment center.

If you currently use plastic stretch wrap to secure pallets, it might be time to switch. HexcelStretch™, our paper-based pallet wrap, offers 30% better load stability than traditional plastic wrap. That means:

- Less product damage during transit

- Safer handling from employees

- More consistent protection for your goods

Like our other materials, HexcelStretch™ uses the same innovative slit-paper technology and is available in three different sizes to suit your needs. It’s also compatible with our custom dispenser system for fast, efficient application.

Whether you're shipping your own products or managing operations at a warehouse, distribution center, or logistics center, HexcelStretch™ makes it easy to go plastic-free, without sacrificing performance or safety.

Let Us Show Your How to Pack Without Plastic

Curious how products can be packed without plastic? Send them to HexcelPack! We’ll repack your products using our sustainable packaging materials and ship them back to you, so you can see just how protective they are.

Whether you’re ready to switch to sustainable packaging or looking to streamline your packaging stations and material handling processes, our team is ready to help. Contact us today.